|

2010-07-26 10:47:28 (6184 views) First, the view count started to look a bit higher than normal. Turned out sessions were no longer being considered by the algorithm. Tracked it down to a "table full" mysql error. Contacted the host, a company claiming to give 24/7 support. Turns out that's level 1 support - for any real issue you have to go to level 2 and beyond and you do NOT get phone support.

They've been playing with it for a few hours and not reporting any progress by mail. After a while more tables became "full" (we weren't able to post any blog entries tonight) and eventually the guy managed to first disallow remote access, then disallow even control panel access to the database, eventually even the site could no longer pull the information!

Then again the site was reading data but writing was still impossible. Fortunately by that time we had uploaded a database backup script and saved the database to a text file, which we downloaded.

We just created a new database on the host and reuploaded the downloaded data, then switched the database that the site points to. At this point everything is working again but it was very close.

The upload process didn't work so well and some tables weren't saved, but fortunately the only missing one that is needed is our notify list table which by total coincidence we had backed up earlier today! Many rows were corrupted in the old forums due to the total junk the spammers had tried to inject in the old forums; so the information was there but we had to hand stitch a 20 MB sql dump in order to get the database to accept the upload data.

We will soon need to switch to a more expensive hosting company with decent support!

If you have registered but can't access the forums or any other strange stuff happens, please let us know. Also if you have signed up for the notify list in the last 24 hours it may be worth doing that again, the system doesn't store duplicate information so it won't hurt. We were testing this throughout this incident and there were at most 5 mins of downtime (because this particular table didn't become unwritable) but just to be on the safe side.

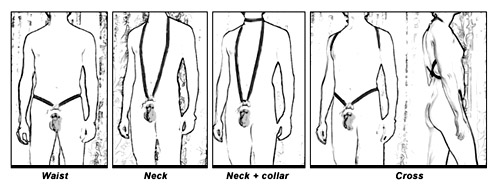

2010-07-26 02:02:12 (6153 views) We've received a longer than normal elastic band sample. This prompted some testing. It seems a "body band" would be more valuable than a mere waist band for our product. Some styles are shown below:

Worn under clothes, the waist style is the simplest and most comfortable. Other styles are a lot more attractive when clothes are not worn.

The body band, when tightened, pulls the chastity device towards the pelvis for increased comfort, security and visual appeal. This enhances contact with the electrodes and the arousal inducer optimizing their functionality.

Ensuring the cage pushes nicely against the penis at all times has other beneficial effects: it helps the male remain aware that he is "on duty", enhancing his posture and quality of service.

The sample we tested is very comfortable and it's made of thick fabric which can expand to 200% its original size.

2010-07-25 23:31:31 (8360 views) The complete DL2000 including the arousal inducer was tested (with a CB6000) for a full day. Here are the results in misc order.

COMFORT

The level of comfort was pretty much identical to wearing only the CB6000. Initially some skin got caught between the inner cable (the cable connected to the inner electrode) and the ring but sliding the cable inside the ring fixed this. The arousal inducer and inner cable occupy a fraction of the space within the cage, however because the penis is tightly inserted into the cage and pushed from all directions this doesn't change the feeling of wearing the device one bit.

FUNCTIONALITY

...

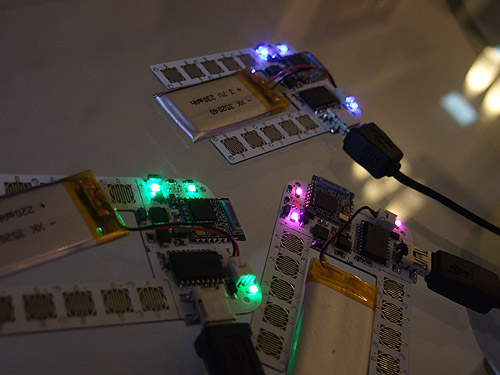

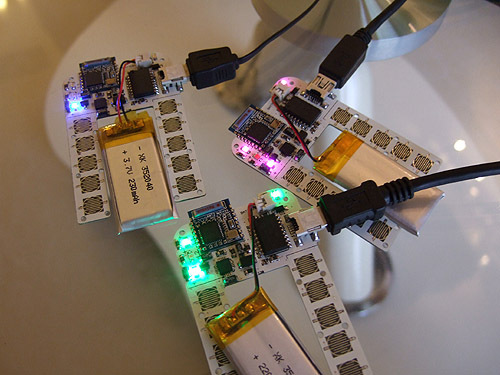

2010-07-25 00:40:48 (5611 views) Some working Arousal Inducers freshly picked from our garden

A bunch of elastic band samples arrived

Some tests

The difficulty is in figuring out how to lock the straps and how to handle different waist sizes...

2010-07-24 05:45:21 (5260 views) Assembled another 2 remotes, so now we have the three samples which will be required for lab testing.

Tomorrow we will assemble another 2 receivers, then we'll have 3 sets!

2010-07-23 23:10:02 (4372 views) After many mold modifications, and heavy tweaking with temperatures, pressures and curing times at different stages of overmolding; after trying different strategies and industrial materials to prepare the motors to withstand the heat and pressure; after fixing even the tricky problem of the motors moving *inside* the mold (when the rubber is liquid) thereby compromising waterproofing, we now have a 91% success rate (10 samples out of 11 trials) manufacturing this very complex overmolded miniature super-strong vibrating motor add-on for the DL2000!!!!

To give you an idea about the difficulty here, a rep for a big prototyping and molding company in the US (big name, all over google) came over to guangdong last month (Jason is his supplier). We met him for lunch at a Chinese restaurant with Jason. He looked at the overmolded motor and looked very puzzled. He said:

...

|