|

2010-12-01 06:42:07 (8521 views) Free goodie with all DL2000 units! Much more convenient than a USB cable.

2010-11-30 22:57:40 (7306 views)

2010-11-29 08:08:38 (8032 views) The LVD testing survivors have arrived. One remote is damaged, two remotes and three receivers still stand (after two different tests, getting zapped with ESD and overheated and shorted in all possible ways!)

With these we're moving ahead and finishing up the last safety bits and we're also starting on the documentation.

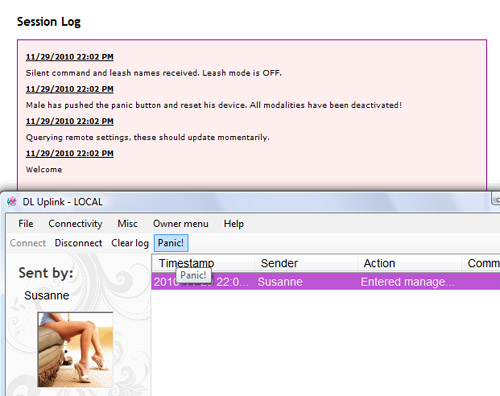

Today a panic button was added that allows the male to reset the receiver and turn off leash/canine/timer and all other modes in case of emergency.

The administrator can disable this button from the DL Uplink's admin panel locally.

In the context of on-site male training the panic button will probably only be used when the parties are familiarizing themselves with the device and the DL2K-LINK is plugged into the male's own PC.

Remote managing users won't be able to disable this button, but if the male clicks it during a sessions, administrators will be notified.

Additionally, when the administrator enters the management session remotely the leash status (on or off) is now displayed. This prevents an administrator from thinking the leash mode is still active when the panic button has been used while they were offline.

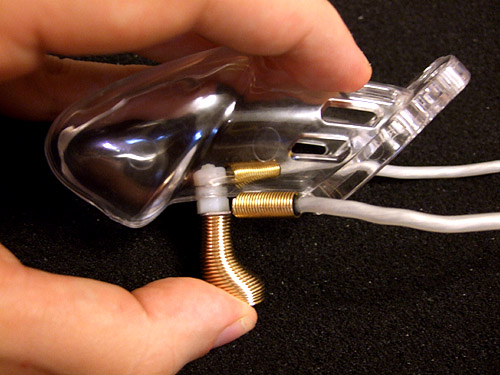

2010-11-29 03:54:40 (7874 views) Our current electrodes were chosen among a variety of conductive metallic parts. In this choice we focused exclusively on the "feel" and comfort of the electrodes.

Other alternatives exist. A couple of weeks ago we were experimenting with a "Tesla" DL2000 which uses spring electrodes.

This far cooler looking alternative turned out to be less comfortable on the scrotum when sitting, and to add a slight "electric sting" feeling to the pulse (due to the smaller contact area on the bottom electrode).

We have many good looking electrodes at our disposal including some that look like jewelry. They all work. However, the large contact area of our default electrodes (the S-shaped and round parts on the upper left) gives the DL2000 its unique feeling and all other bottom electrodes reduce this property by 20-30% depending on anatomy and positioning of the penis inside the cage.

If we ever create custom metallic parts the lower electrode will probably look similar to what we have now. Perhaps a bit thinner, and curved, but necessarily of similar size. This is a long due clarification as some have pointed out the electrodes may be the most "low tech" parts in our product; however they really are the best performing ones.

2010-11-24 02:54:22 (8070 views) Done in Taiwan this time. You can see the difference. Finally they managed to use 0.5mm thickness PC without excuses, wrong hole positions, glue sticking out of the holes and all the defects we experienced. These overlays are finally completely flat.

The overlays have finally reached the quality of the other DL2000 parts.

2010-11-23 05:37:22 (7345 views) HARD WORK is what it's taking to make this product a reality!

Today we celebrate...

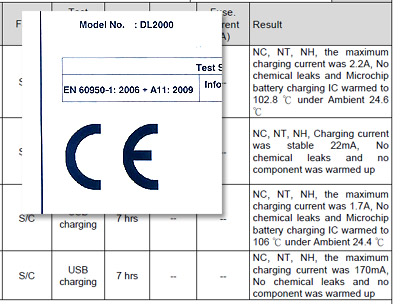

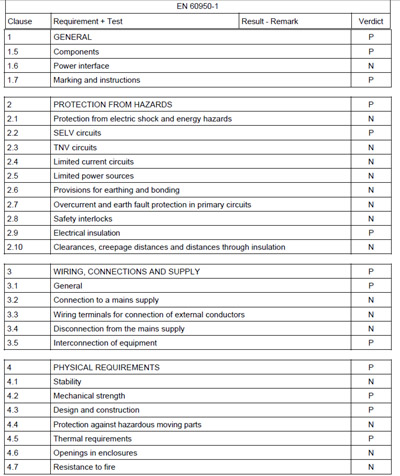

The DL2000 has officially passed all regulatory testing for the US and EU and now has the "CE" conformity mark!

|