|

2010-11-21 04:03:13 (7646 views) Good band located!

- non stretchable

- made of synthetic, thin material. Looks and feels cheap but dries quickly.

2010-11-20 10:30:25 (6935 views) One of the hardest things to build here in China.

It would be easy to use this kind of system

but then it would be very easy to take it off.

We can use something with holes to allow you to lock the band with one of those plastic locks commonly used for chastity devices. But the waistbands that already have holes are a bit odd.

So we're still trying to make our own holes. We've abandoned the idea of putting eyelets on these bands because they look terrible (the back of the eyelet gets deformed, sometimes the front too). We're now working with shirt buttonholes but here too it's mostly a manual job so the positioning, angle, etc. can't be controlled and the result is very poor. We went to the factory to do this together with the worker and managed to improve quality by 30% just by telling him "do it again" whenever he made a bad hole. But it's still not enough. He's saying they need a computerized sewing machine to do this job better, and they can rent it. So we got more material and on Monday they'll give us an appointment to test this new method.

As you can see it's all very difficult and error-prone, we wish there was an easier way to hold this waistband in place securely (at least a tamper evident method).

2010-11-19 07:27:03 (6830 views)

2010-11-19 04:23:47 (6409 views) Another factory visit trying to get the waist/bodybands sorted out.

This is the best result we could get with the machines they've got. Eyelets are always squeezed so we abandoned the idea and resorted to trying to make shirt button holes. The problem now is that it's really hard to position the holes. Even with us on-site trying to fix things up the machines aren't precise enough and so the results aren't very professional.

Still, this is better than nothing - they may not be pretty but at least they do the job they're supposed to do. There are a number of holes which you can use to lock the band behind the back with one of those plastic locks, or other means.

Trying to find a factory with better machines to improve the quality a bit more.

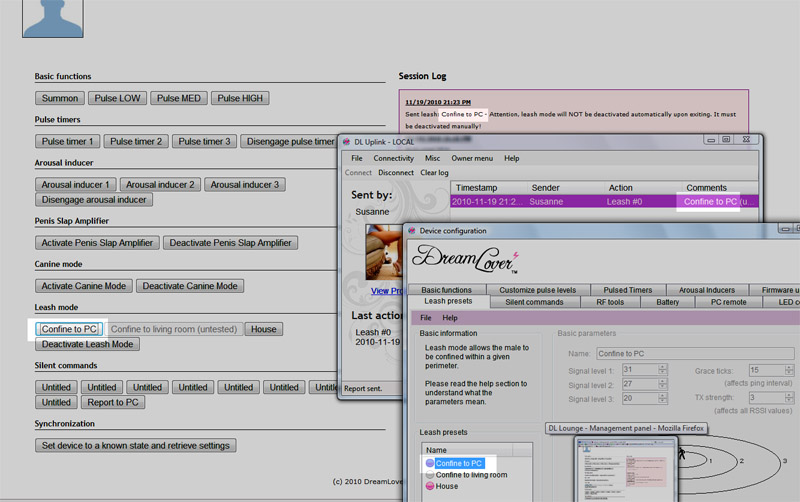

2010-11-18 12:08:16 (6583 views) As you know signal strength is affected by walls and surroundings, so the same values can give different results in different situations. This creates a problem when you want to remotely activate leash mode (through the internet).

As a solution, the leash ranges screen has been changed to "Leash Presets". Each preset contains all the information for the ranges and timing as well as a name. Local administrators can create presets and store them. Presets are tagged as "tested" when you push the transmit button with the "simulation" checkbox checked.

For safety, remote users will be able to trigger tested presets only.

Future updates may include the possibility for the remote user to ask the local user (managed male) to download presets and test them, after which they will become available for remote activation.

2010-11-17 06:55:06 (6718 views) Hundreds of types of paper and cardboard. Intense color experience. Huge machines that cut, bend, fold, pamphletize, bind, stitch, glue, laminate and more.

A tiring day of negotiations! They gave us a high price because of the "imported materials". Then we changed materials and the price didn't go down, now they said it's the color. Changed the color, still price remained the same because of the silver stamping. Ok, no silver stamping how about printing. Price unchanged, now they have set-up fees. But subsequent orders will not have set-up fees, right? Wrong. They want a set-up fee for EVERY PRINT RUN.

In the end it doesn't matter what we choose, 4 layer boxes with silver stamping, gloss surface and black cardboard, or junk brown cardboard that looks like supermarket left-overs.... The price is the same. Now escalating this to the CEO who seemed friendly but had to run out in the middle of the meeting to pick up a payment (lucky him).

Negotiations are tricky but math helps. See, they claimed they had basically no profit and that material costs were 80-90% of their estimate. But, we tried to ask the price for double the quantity and surprisingly the price went up by less than 30% (it should have almost doubled for their story to check out).

They didn't expect us pointing out that the amount is too LOW, so they were caught off guard. The only way out was for them to claim there is waste material. To back up the initial story they had to set the scrap material to 33%. In other words for every 100 square meters of material they would waste 50. That doesn't sound right. We're already calculating the box cut area as a square so all the waste material at the four corners is already accounted for. Here they're saying they literally throw away 50 square meters when they begin a job ??

The real problem is - as usual - quantities... If you make 100,000 pieces of something you pay cents per piece, doesn't matter if you're printing, sewing, stitching, assembling PCBs or buying components. If your quantities have only two zeros then you're really asking for trouble.

No factory wants to take a job with less than 2-3000$ profit. Even if they rip you off, they're still doing you a favor by taking the order... These machines are huge, they look like newspaper printing machines with hundreds of perfect color copies coming out each minute.

The smart thing we've done is to find a factory that can do everything (foam, molds, cutting, laminating, stamping etc). Incredibly the price for just the foam at a foam only factory and the price for everything including instruction booklet and stickers at this comprehensive factory is almost the same! Which again proves all the calculations are bogus they just decide how much they think they should be making to take the order and then divide by the number of pieces :)

This isn't over yet! Round two coming up tomorrow...

|