|

2010-05-20 07:20:49 (5707 views) One of the important tests to be carried out... On low battery, receiver does not break or hang. Delivered current is lower and lower voltage, motor vibration is reduced, until eventually a pulse delivery attempt just resets the device, an indication that the battery must be replaced.

2010-05-20 00:25:00 (5805 views) Please use this forum to contribute ideas/pointers for inclusion in our documentation (instruction booklet to be shipped with the product and online help). Old blog questions should be moved here...

2010-05-19 23:53:57 (5292 views) After going ahead and shelling out yet more cash to mold metal pieces to be attached to the motors, so as to make Mr Tang's job simpler (he already messed up 70 motors and we still don't have a good, clean and professional outcome), now the company that welds the metallic bits to the motors used such a pressure and temperature that they melted the motors and the metal bit together and the two are damaged and looking real bad - the 10 test motors probably got damaged in the process, but it's useless to even test them because the amount of molten metal on the bottom will create problems for the mold.

Today Jason learned for the first time that Mr Tang has already consumed 70 of our rare motors (maybe 75). He said from now on he will manage this himself, which is really good news because he is the only person in China who has consistently solved problems and never lied.

In the meantime, we already waited 24 hours for the assembly house to OK our new remote control design, and now they're saying it has a problem, but won't say what, and we're again waiting.

...

2010-05-18 23:47:11 (4547 views) May 18th, 2010: the date the first Male Management Company was created. Write that on the history books! Or better, on Wikipedia.

We're waiting for official documentation and we will then proceed to open our corporate bank account. With that done we will apply for payment processing. THEN we will finally be able to operate our business.

...

2010-05-18 10:58:13 (4452 views) The "rotated antenna" mod to these RF modules greatly extends their range.

A few days ago we had a problem and the thing didn't even work 5 meters away. But passion and perfectionism win! Now the signal can reach the other side of a pond about 100 meters away.

...

2010-05-18 09:24:43 (4646 views)

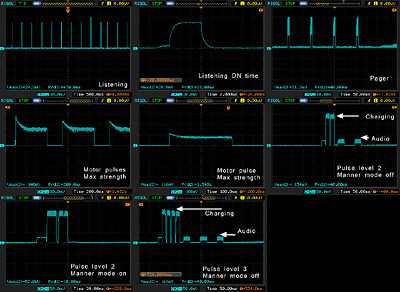

The current was measured through a 1-ohm resistor, therefore all readings in mV correspond to mA of current.

1. Listening. These values are a bit on the high side due to RF testing, they may come down by another 20-30%. Presently the ON time consumes 28.8mA for 6ms, which is equivalent to 0.000048 mAH. The cycle is repeated every 470ms. So every hour the device uses 0.367659mAh. That makes the 700mAh battery last 1904 hours or 79 days (2.6 months) when the device is never activated

2. The pager consumes an average of 20mA for 10ms each pulse, and the pager sound repeats this pulse 4 times. Therefore each pager activation uses up 20mA for 40ms. With one battery you could page 3,150,000 times without taking into account the listening overhead

...

|