|

2010-09-25 09:17:45 (6751 views) Good progress today on the batteries, seems like we won't have delays because of this component. More when we have a final answer probably on Monday.

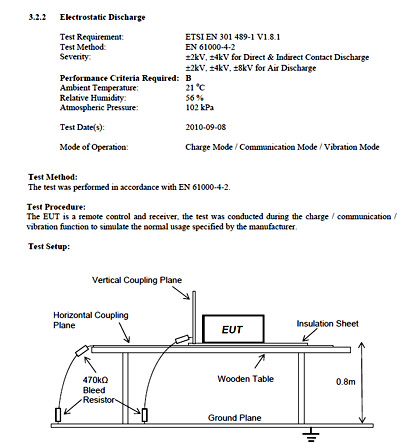

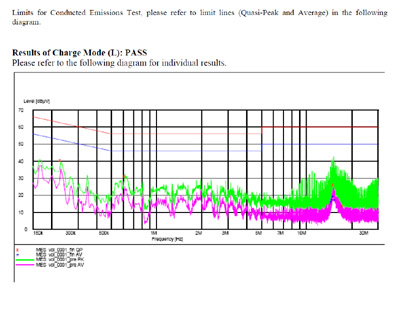

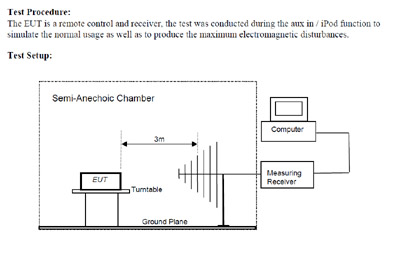

2010-09-23 06:29:26 (6918 views) Except for a careless mention of "i-pod/aux in mode" which seems to be a leftover from whatever previous document was used as a template (soon corrected, we hope), the test reports for US and EU seem good. A few interesting diagrams:

The product does many things, but one thing it's not going to do is play your MP3s for you... please strike out the i-pod mode! :)

Assuming there are no battery certification troubles this report makes us good to go for the US and shortly we'll have the LVD stuff for the EU.

2010-09-23 03:19:21 (14348 views)

Please visit this page for a comprehensive overview of remote control button mapping and device functionality.

This page will be pasted as-is into our documentation so if you find any hard to understand or confusing points please let us know and we'll improve this as we go along.

2010-09-22 00:01:53 (5689 views) Unable to report all the complexities we're going through because stuff is really going out of control as we near product launch, new issues pop up daily and we'd have no time left over to complete the product if we reported in detail on everything worthy of mention.

There was the issue a few days ago with the testing lab trying to trick us into doing spectroscopy testing for our LED, against the opinion of all other testing labs including the very big ones in the UK. Stubbornly as always, after a heated discussion with their LVD engineer we went to the specsheet trying to prove math is not an opinion and that this LED would never exceed EN60825-1 class 1 exposure under any condition.

Lots of calculations in unfamiliar and groovy units as we went from millicandelas to lumens using the viewing angle value and some internet conversion tool. Lumens then converted to millijoules per second using "photopic" wavelength tables from earlier internet years (but still valid).

mJ/s then converted into joules per square centimeter and compared to the curves of the 60825-1 maximum permissible exposure ordered by wavelength (luckily at least this stuff is public).

Turns out unless you shoot this led beam straight into your eye and attempt self lasik correction (which is not possible since it's mounted 90 degrees with the PCB) you will never ever reach the MPE levels. The very fact it's at 90 degrees makes only a fraction of the power ever reach your eyes, but the lab didn't care and they just wanted the money for the new test because they had to buy their new spectroscopy equipment for the new photobiocompatibility rules of the EU (which by the way SUPPLANT 60825-1 as of Sep 1st, so why are they even mentioning it) - so we went back to the search engine and now we found a new lab, and they don't even need the calculations - indicator LEDs do NOT need this kind of testing!

We're getting pretty comfortable with european union directives at this point (which implies a certain degree of madness or at least being able to penetrate a very unusual and paranoid mindset) - but that is causing more trouble as we found out our battery manufacturer gave us a CE certificate that:

(a) is for the wrong battery

(b) mentions the wrong test standards

and therefore is likely forged. No mr Ferris sir, you don't test batteries for EMC, that's for products, we know something about that now! The manufacturer even offered to MISLABEL our batteries to make them match the report! If that doesn't cast some doubts on everything he will subsequently provide then what does? This is how it's done in China - got a test report problem? No worries, pick an existing report, and re-label your product. But hey, there's worse: some vendors think they LVD tested the whole factory so that anything they put out now is automatically certified. :)

Before you panic - there is absolutely no risk with the batteries we're using because their volume is so small; all shipping regulations begin at a few grams of lithium per cell and we're at zero point something lithium gram equivalent. We tried shorting the batteries without even the protection pcbs attached (!don't try it at home!) and they only marginally heated up, no inflation, no fire, nada (a bit of a disappointment really after taking extreme safety measures for this experiment). So the safety here is absolute, but alas, small batteries must follow the rules for big batteries, as is often the paradoxical case for such regulations.

So another adventure today trying to find out what test standards lithium batteries need to comply with, turns out Underwriters Laboratories has one standard, UL1642, but likely it's the United Nations one that is legally valid, including shock, vibration, heating, low pressure and other tests (T1 to T8).

Also there are severe transportation regulations, which are in addition to safety testing burdens (IATA and US CFR 49 comma something). Then, Fedex USPS and other carriers have their own lists of rules (with complicated charts and tables and yes, arrows and such) which tell you what you need to declare/provide/sign based on how big the battery is, whether it's integrated in the equipment or not and so forth.

Madness ladies and gentlemen. Numbers and units spiraling out of control in an infinite vortex of lysergic legislation as inert components are accused of a conspiracy to blind deafen and obliterate mankind through their nano-stored energies.

We'll win in the end, and we'll be more prepared for the next product than any company out there. Seriously. Our RF manufacturer doesn't know the difference between EN301489-7 and EN301489-17. They got it wrong on the spec sheet. We point out errors now to vendors with much bigger businesses. We communicate in numbers with the testing labs (sample question from a couple days ago: "Does 60950 include 60825-1 even when applying for 301489 certificate through annex 2?")

However... at this point we politely request that these legislators give us a break! At the very least, ALL these rules they come up with should have exceptions below a certain limit. Like, if your LED operates at 3.6V and it's got a 1K resistor in series, its maximum current can't exceed 3.6mA and therefore with current technology the thing Can Not Blind You Sir. Or... if your battery is flat as paper and smaller than a stamp, you should not have to do altitude tests at 5000 feet... wouldn't that be convenient!

On a more general note isn't there a free market way of forcing manufacturers to put out safe products? What about a big internet shame list connected with your i-phone which lets you scan products at your electronics store and superimpose the bad guys in augmented reality plus the blog pictures of their exploded units :)

As in most things, there are some clever ways one can think up to get governments out of the loop - untested, possibly promising, but hey - we're stuck with what we have.

For now, we're dancing on the big guys' stage and we can't choose the music. TLC, Rimsky-Korsakov or Dr. Dre, those feet have got to keep moving... All we have is a special product and a special audience. With this we'll claim our piece of land soon despite adversities and then all will be smoother...

Some Chinese holidays coming up but we'll have the 100% final, diamond polished mold this week.

As for the battery problem we're not TOO worried, we already have 2 labs we're talking with, one UK befriended lab technician, and plenty of battery suppliers to choose from... we'll either find someone who's got the paperwork, find a way not to need any, or do some testing ourselves. We'll work something out!

At this point we're looking at the end of October as a possible "Product Complete" announcement date (product complete, in good legal standing, and only shipping left to figure out). It's not easy to predict things exactly when we're having to do all the work our vendors and labs are supposed to do. We're working on a pricing strategy to allow us to move to mass production as quickly as possible, here again it's not straightforward for a number of reasons including the fact that the word of most suppliers cannot be trusted. Until the courier guy rings at the door with the shipment we cannot assume they won't try to change the price on us.

We absolutely did not expect having to pull out hair to prove the intrinsic and evident safety of each individual component in the product.

Fortunately there are people working on the mold, the rubber and the bodyband as we speak. As long as stuff is still getting done we can use this time to sort out the legal stuff. If when everything's finished and ready to go we're still studying product safety laws then that will make us a tad nervous. For now we're sailing ahead at full speed towards our destination, as promised. What a ride.

2010-09-21 10:39:55 (5668 views) One of the realities of doing business with China. Everyone's trying to raise the price after we've already accepted their quotations. The testing lab is saying we need to test the LED to laser safety standards. The PCB assembly house forgot - whoops! small detail - to add the cost of the stencils to their estimate. Stencils are several micrometers thick laser cut metallic masks used to place solder only on the PCB pads.

We're fighting hard to avoid getting whacked at every corner and we've been fairly successful up to this point. We'll move the LVD testing to another lab - they seem more honest and will do the job for less. The assembly cost went up but only by a bit, not the amount they had in mind.

The good news is that we were able to test the few components that have substandard packaging or other strange properties, and determine that all can be handled by the assembly machine.

One of the components in particular uses a reel whose compartments are too wide, so there is some uncertainty in the position of each chip; if the machine isn't able to precisely pick up a component then its PCB placement may also be uncertain. However, their machines are truly state of the art with robotic vision algorithms that can visually determine the exact location of the chip that's been picked up! We did a test pick and place and we can gladly announce we don't have a problem after all.

Having renewed our arrangements with the PCB house all is pending us getting enough cashflow to bootstrap this process. As planned we'll be manually assembling the very first units and as shortly as possible after that switch to machine assembly.

Machine assembly is vitally important to be able to put out enough pieces to satisfy demand. Assembling one remote and one receiver by hand takes 3 to 4 hours, and the PCBA guys themselves confirmed this is how long it would take for them to do it manually. Machines can do the job in 5 to 10 seconds per set!

Hard day, but - mission accomplished!

2010-09-19 09:17:00 (6094 views) Today the last remaining bits of the firmware were completed.

1. The remote control firmware can now be reprogrammed just like the receiver's and the DL2K-LINK's, ensuring maximum flexibility for tweaks and updates in the future. We will continue to polish the firmware until the release date.

2. The last firmware feature was implemented: silent commands. Silent commands are vibration patterns (sort of like morse code but more precisely like a monotonal melody) used for communication with the wearer. There are a total of 9 possible patterns. They can be manually, programmatically or automatically activated. Automatic activation for now is only used when the receiver enters canine mode - this gives the wearer a necessary advance notice that this mode is being entered. Manual/programmatic activation of the other 8 commands is triggered with the remote control or DL2K-LINK.

Silent command codes require some learning; for this reason they will be integrated with our courses. Negative/positive feedback e-learning should allow quick memorization of these simple patterns. Both the pattern and the corresponding meaning will have a default (for now only patterns have been decided) but they will be easy to customize.

When will manual/programmatic activation be useful? For instance:

- speech is impossible (due to distance or for privacy reasons) or undesirable (full robotic control of the male wearer is finally possible)

- DL2K-LINK is used to issue timed commands (think of it as "task manager" for your male)

|