| << return to blog entries

2010-04-21 23:32:06 (4777 views) First the really important stuff - here are some results from the magic "nail printing machine" as seen at the Canton fair.

What's that? Oh you think they were printed in reverse heh, you anglosaxon colonialists... Chinese is traditionally written right to left so it only makes sense that the machine should output mirror images of any file it's fed :)

Miss Kim had these on for days now. She really likes them.

Now most people think far eastern cultures are still very much patriarchal in nature, however feminism is making great covert strides in this region, as highlighted by this telling restroom sign we've discovered. If this is not making a statement then ... then ... yin is yang ok?

And speaking of yin and yang here's how our new LED manufacturer answered our inquiry.

"Dear sir, I have one question about 5mm RGB,This product is a total of yin or yang and What is the use of the product?Thanks!"

Not sure what buddhist translation software they're using but this line definitely got us thinking.

Now... the question that drives us is "when will the dl2000 hit the market?" - let's take the red pill. But before we do and since we're speaking of pills, let's face an important fact.

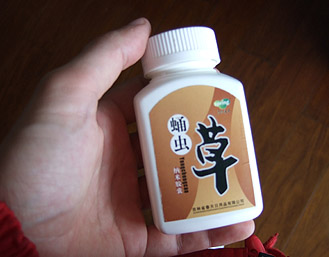

Lack of North Winter Insect Summer Grass in the diet is a well known cause of... bad stuff happening all around you. So it should be very good news that THESE North Winter Insect Summer Grass capsules are embedded in nanocapsules for easy absorption. Why Miss Kim came home with something like this shall remain a mystery.

To proceed to the serious stuff, we've decided to examine the "ETA to launch" issue in reverse. The goal is to start taking orders and ship out products. To do this we will need a bank account with payment processing, and a fulfillment center at least in the US (and the EU coming up soon) with our product neatly stacked on their shelves and ready to dispatch upon receiving an automated e-mail.

Right now the process of obtaining the right structure for payment processing is under way. We've tentatively cleared the chinese/english address problem and upon receiving an official OK we're sending the payment for first year and incorporation expenses. It will take about a month to go through this process; then with all the company info in hand we'll need to apply for payment processing, something we've already worked on at length, we just need to send the appropriate forms and hope we don't get turned down again. The good news is that we'll be able to accept wire transfers as soon as the account is set up, without having to wait for credit card processing. That is not a wonderful solution since international wires can cost quite a bit, and the alternative (xoom.com) sometimes sends you back the money - but it's better than nothing. So the ETA on accepting payments is 30 days or so (that's days, not business days).

Fulfillment is not a problem, we just need to send a bunch of units to the fulfillment house in the US (and EU later). Now the little problem here is that we don't know what rate customs will charge us, because their binding ruling request was not conclusive and they need to get samples. This is a little problem because the worst case is that we get hit with more tax than we should be paying, for our first shipment. It's not a show stopper. The bigger issue is that we don't have product to sell. This pretty much stops the show like the main star recovering from a cocaine hit in the changing room and being basically unconscious as the cameras start to roll.

In order to ship we need to have a box full of DL2000 units properly packaged and ready to go.

This requires as a last step, to assemble the product (put the PCB inside the housing, put the grommets in, put the cables through the grommets, fasten the ring terminals, and so on). This can be done in the US or China depending on which is cheaper (for instance if the rate to import the final product is 10% and it only costs 5% to import plastic materials and printed circuit boards, then it's going to be cheaper to import the parts and assemble them for 35$ an hour than assemble them here for pennies). So the location where the final product will be assembled has to be decided, and the possibility of course exists for sending the parts and letting you assemble them yourselves. It's not that hard, really. We'll see.

At any rate, in order to assemble these parts we need to have the parts, obviously. So it all comes down to how quickly the parts can be produced. But before production they also hopefully have to work. Waterproofing must be fixed 100%, there is really nothing else that is still not working. We won't even mention the vibrating motors here since we are not dead set on shipping with them. The plastic housing and PCB are ready to accommodate the motors as an add on which can be purchased separately. However our opinion is that we have 90% chances of being able to ship with the motors, as the manufacturing issues have been almost completely ironed out.

So what is it going to take to fix waterproofing? The o-ring and screw rings are already 100% waterproof. The motor cable grommet also works 100%. The problem are the two main cable grommets. We've made the size smaller but it's still too big. We're switching to a softer cable; the elasticity of the cable exterior is an integral part of the waterproofing and it seems that the smaller the hole and the thinner the grommet wall, the more cable elasticity becomes important, as this creates more elastic mass which can push tightly and prevent water molecules from getting in. Water molecules are... pretty small.

This is an easy thing to fix, Mr Tang's already changed the grommet mold (again) and we've ordered a new softer cable which will get there tomorrow. So sometimes next week we should be announcing complete waterproofing success.

Something needs to be said about waterproofing. You have to be careful when you close the device. Is the grommet partially sticking out of the hole? That's bad. Is the o-ring sticking out of its groove? Same story. Now, we're testing with strong water jets and submerging the unit entirely under a foot of water and a fish will be introduced soon for dramatic effect and photo ops. Chances are even if you go in the shower with a badly waterproofed unit you will not immediately fry the pcb; the water is coming from above, and the grommets are below the unit. However, obviously, the stronger the water, the longer the time, the more opportunity the water has to reach sensitive parts of the PCB and short circuit it. If it does short circuit you may have a chance to revive it by putting it in a jar filled with rice and leaving it there for a couple of days. This works for cell phones too; rice absorbs any moisture. The chances of this working are high if at least a minute or two went by since the last pulse delivery. Otherwise there's a capacitor on the board charged at 24V and if that shorts to the RF module then - well, don't short me bro.

So obviously waterproofing requires some attention when you close the device. After that, just don't pull on the cables with all your strength while you're under the shower, and you can pretty much forget about it. We plan to take this scuba diving by the way (as soon as we can get out of China). The pulse likely won't work but at least we'll know if waterproofing is still reliable 10 meters under water. Waterproofing was so hard we're dying to show it off! Picture this: guy with nitrox tank, mask, funnel, a DL2000 worn outside the wetsuit, thumb up and bubbles everywhere. Cheesy photoshopped balloon: "Yes, it's waterproof!". Speaking of which... are there any femdom mermaids out there??

Now... with waterproofing solved we just need to create the parts. Creation of simple rubber parts will only take a few days, whereas the vibrating motors may take up to 1-2 weeks depending on how busy Mr Tang's factory is. But we should begin this much earlier than the bank account is set up, so there will be no delays.

Plastic: this is the largest and most expensive mold that we have to create, and Jason said it will take a month. So there may be some time after we have the bank set up where we are still waiting for plastic. We also need to do some testing for the final material and finish. Do we want polycarbonate or ABS? Spray paint? Just add glitter to the ABS material?

It doesn't help that all these deadlines are sort of interlocking. We need to be 100% sure waterproofing will work with our current plastic design before starting the plastic mold carving. Who knows, we may end up discovering the wall is too thin near the grommet. Can't risk wasting a mold. So, first things first.

Ah, forgot everything about PCB assembly and certification. PCB assembly should take only a few days for the first small run. Certification will only take 2 days but it may be 2 weeks before they will receive us. Now brainstorming about when to do certification, the product CANNOT change at all after this is done because we can't afford to do this twice. So the longer we can postpone this the better.

So this is the complete landscape of what we're working with in terms of interlocking to-do items and milestones to launch. If we're lucky we may be launching in only two months. If not, it may be 3 or a maximum of 4 months including credit card processing.

We've got back up plans in case any element fails. If card processing doesn't go through we'll do wire transfers in the beginning. If we don't pass the certification tests we've already made a deal with the testing lab to bring our tools and make mods live to the circuit until we pass (try do this in the west!)... and also they will examine a sample pcb very briefly before we even go there so that if there's a cockroach in the cake we'll know before the guests arrive. Hey we're getting good at gross analogies. Must be the summer insect grass.

Bottom line we have a plan A, B and C - we're unstoppable!

Coming up in the next few episodes: new factory trip to verify motor overmold reliability and final grommet sizes (possibly 100% waterproofing success announcement), trip to the pcb assembly house more than 3 hours and 3 bus rides away, new prototypes with light pipe design, spray painted and with black attachment rubber and white thunder, new white PCBs from Korea...

Comments

Post new comment

|

We my have a new Sci Fi movie script right there.

This will not bode will -- many males who cannot find a wife. It could conceivably lead to war (to prevent civil war), which would allow China to simultaneously cull the herd as well as accomplish other objectives (such as invading Taiwan, who knows, even Japan).

Solution: 60 million Miss Kim clones and a production run of 60 million DL2000 units! Luckily, you have 10 years to accomplish this at a reasonably slow and comfortable pace. :)

Instead, we'll need a huge production run of maybe 700 million DL2000s (over time) to control the entire Chinese male population, and allow females to "own" more than one male husband, purchased on an open market.

You can still offer a combo-package of DL2000 plus Miss Kim clone for sale in other countries.

You're going to have to ramp up that DL2000 production a bit faster than planned.