| << return to blog entries

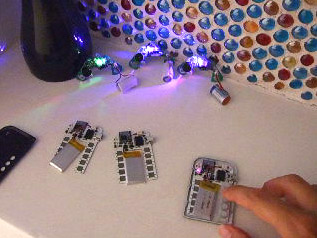

2010-07-27 03:45:14 (7688 views) A very hard day of soldering and the boards (3 sets of receiver and transmitter) are ready for lab testing.

Total headache when one of the RF modules was found to be defective after it was soldered!

This castellated 12 contact module is very tricky to desolder. Two soldering irons (and two hands) were used for lack of a better tool. Even with a heat gun it is probably very tricky to get it off because there are many 1x0.5mm SMD components on it and these will come off a lot quicker than the pads on the sides...

Fortunately the chip was desoldered and replaced successfully with the two irons technique and now both the two new receiver prototypes work giving us a total of 3 working DL2000 units.

Well... we can't afford NOT to machine assemble these. Putting them together requires prolonged, extreme concentration - it is exhausting work! On the positive side the accelerometer can now be placed without any problem because we've gotten enough practice with the 20 pin 3x3mm leadless package (battery charger IC) that now this 8 pin one seems "easy".

This product is so impossibly miniaturized that even a 1mm error in the length of a through hole component (LED, pulse capacitor) leads makes it impossible to close the enclosure! This time we screwed up the length of one LED and had to cut a piece off :) In the future the position of the LED must be watched more carefully.

Oh, we need to get full color LEDs now. Turns out the supplier never shipped our paid order. Too many things to worry about. Lastly, because we ran out of the right part and used a replacement, one of the LEDs used has inverted green and blue pins (hence the color difference!)

Hard day... soldering this product by hand is really exhausting.

Comments

Post new comment

|