| << return to blog entries

2010-07-23 03:44:59 (3644 views) A small step for the remote, a giant leap for Male Management!

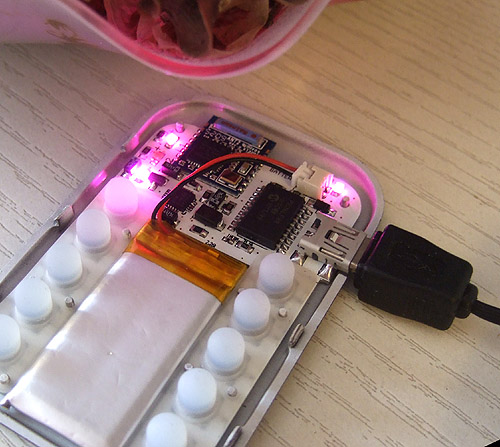

This may not seem like much of an improvement from previous photographs, but our new remote (shown below) should be resistant to several kilovolts of electrostatic jolts which it will receive at the testing lab. It's all part of the fun process of satisfying international import laws and product safety regulations... and part of the difference between a DIY project and actually releasing a real product that you could buy in a store.

What you see is our very final design and if nothing goes wrong at the lab it is exactly what you will receive when you order this product (except that it may be machine assembled, depending on how assembly plays out in the beginning, this is a bit complex due to cost, bootstrapping and the fact that some components do not have the right packaging to be handled by the machines... we're working on it).

Oh yes, the PCB is finally white which was our target color from the beginning. And - finally - it's 0.8mm in thickness, which means we can actually close the remote's enclosure properly! More pictures when we get the first molded parts....

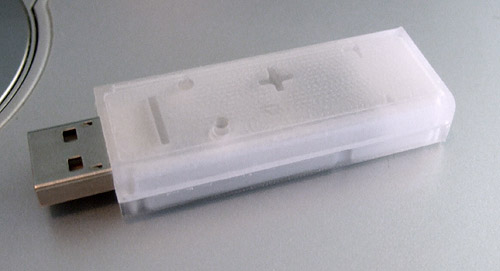

Also: we hadn't reported on the DL2K-LINK's plastic prototype which arrived a few weeks ago. This is machined, and has no label... but it shows the shape. Nothing too exciting here, a normal USB dongle enclosure... however it is our CUSTOM enclosure soon to be manufactured with our mold... and it has a precisely positioned light pipe for the LED to shine through, and a little button which will allow you to reprogram the firmware when updates are released. So we're already quite fond of this little guy which just joined our family :)

Comments

Post new comment

|