| << return to blog entries

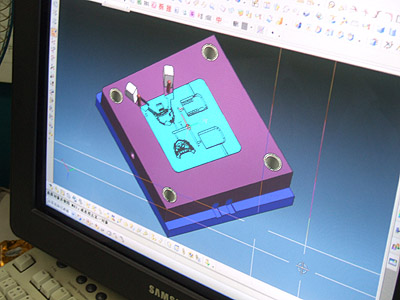

2010-07-02 11:06:54 (10150 views) We have been working with press molds (for the rubber parts) for a few months, but now our first injection mold is being prepared. This is also our first experience ever with injection mold design.

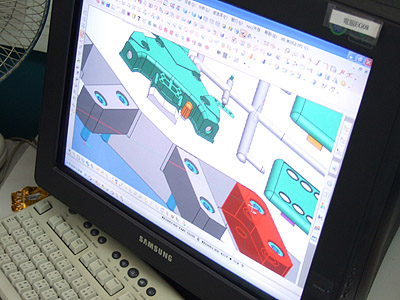

Finally we have understood the reasons behind the very high tooling costs. The mold is very big and heavy (it's made of steel), and a crane must be used to move it around. The part below is just a portion of the mold.

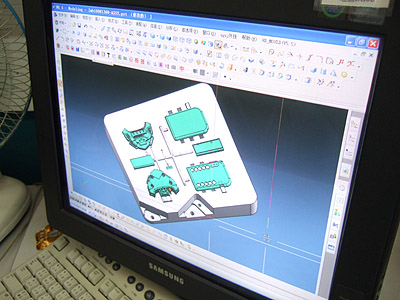

Here's how the parts are positioned. You can see the receiver, remote control and the DL2K-LINK.

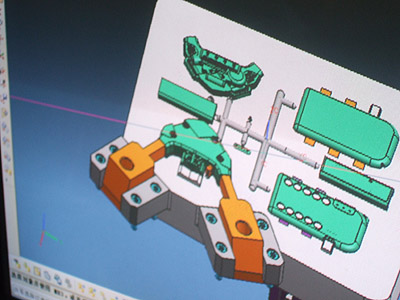

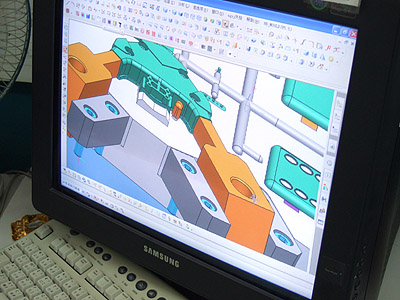

The receiver's holes are undercuts. A sliding mechanism must be used to produce these holes. Many more moving pistons must be precisely oriented in order to push the plastic out of the mold from the bottom when the plastic has solidified.

The mold is really not a static piece of metal but a robotic system including many big steel moving parts. Most of which are completely custom.

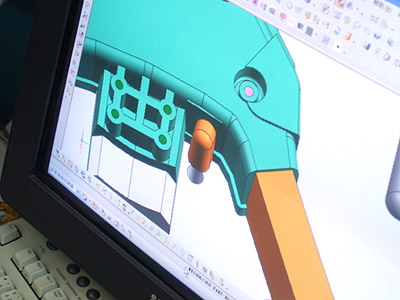

Hand positioned parts (inserts) for our problematic third hole for the arousal inducer (not enough space there for a sliding part)

Then... because we've asked Jason to overmold the brass inserts to allow you to open and close the receiver an unlimited number of times, these must be positioned manually (not shown), and material flow must be planned so that inserts are not displaced.

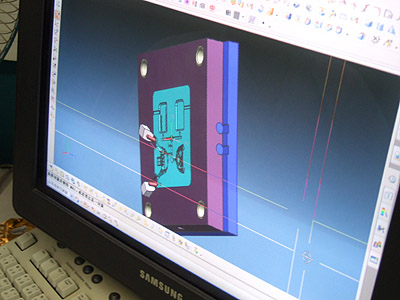

Another two views of the undercuts:

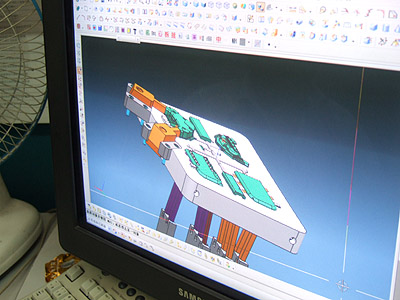

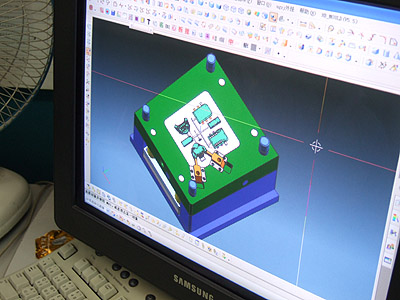

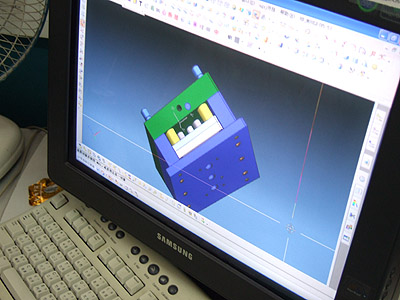

This is the whole bottom part of the injection mold.

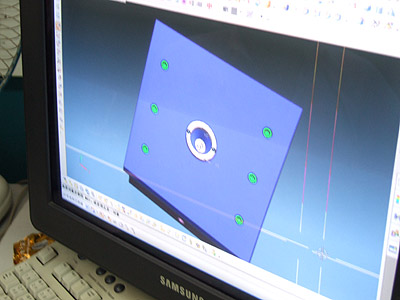

The mold includes a cooling system (shown in blue).

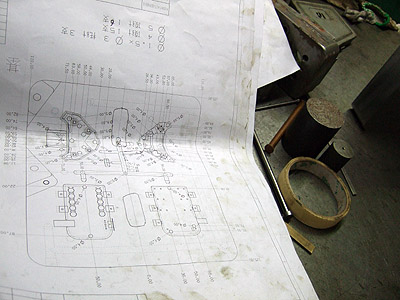

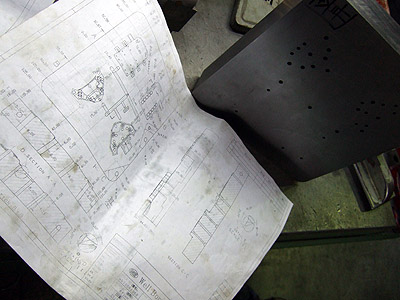

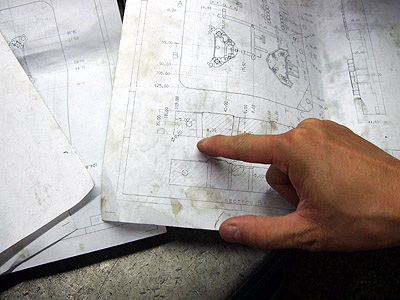

Our mold's construction plans are already being passed back and forth between engineers who're studying them like a bank's floorplan.

The drawings are getting a bit messy with all this oil but the finished parts will be perfectly smooth and squeaky clean. It will be a big improvement from the machined parts you've seen so far!!

That's it. This is the result of two years of work and effort, and we're so excited to see it all coming to life before our eyes. We're also relieved to see that we're really getting our tooling money's worth! The mold wasn't just a piece of steel with some holes into which plastic is poured like molasses, as we previously naively thought as we cursed injection molding factories for their "insane" fees. No wonder tooling fees are high... they're building us a little steel robot here with lots of moving parts, precisely designed with fluid dynamics, cooling and who knows what else in mind - and it's so heavy they need a crane just to move it around! :)

Is this cool or what?

Comments

Post new comment

|