| << return to blog entries

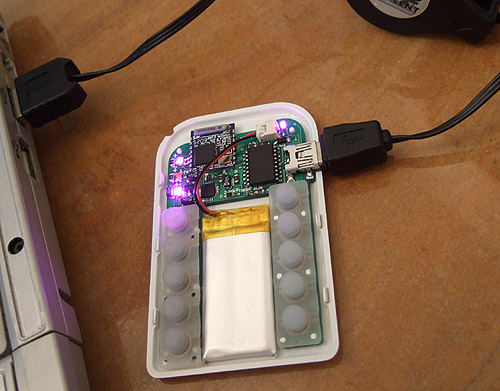

2010-06-12 10:03:21 (8260 views) The new boards have arrived, and a new receiver and remote control were assembled!

RECHARGING

The recharging function works perfectly.

- Only 5 seconds recharging of a flat battery allows you to use the remote for half a minute, which is quite impressive.

- There seems, very rarely, to be a glitch with the circuitry hanging when the battery is allowed to discharge completely. In this case removing and reconnecting the battery fixes the problem. The bug was seen twice but disappeared in all subsequent trials... we don't have any more space to add components to prevent this kind of behavior (technically called a brown out) so it's probably going to go in the "troubleshooting" section.

- The remote has a temperature sensor which will immediately stop recharging if the temperature is outside the -20C ... 60C range. This is for safety when recharging the li-poly cell. The mechanism was tested with a hairdryer and works fine, though for lack of space we do NOT have a fault condition LED to let you know this is happening (instead, the CHARGE LED stays on - but you will never have to worry about this unless you live under a magnifying lens at the equator).

Stupid mistakes were made:

a) new layout has a capacitor right underneath the edge of the rubber keypad. The keypad can be cut without any visible difference from the outside and the problem can be thus eliminated. However we will move this component for the next layout (already updated design).

b) ID and GND pins of the USB connector were mistaken, fortunately they can be shorted without any drawback (this is how we're testing - but we'll fix the boards the next time around)

c) an ESD protection component was not placed due to the fact the layout was created in a hurry (PCB manufacturer was about to go on vacation at that time). This should not make a difference to any users, but our EMC testing includes electrostatic discharge immunity, so they will zap our poor PCBs with thousands of volts, and we need to add this component to make sure nothing fries.

Fortunately these 3 corrections do not impact anything in terms of plastic enclosures, programming and so forth - which means a new prototype won't hold us back. We will in fact very shortly (Monday or Tuesday?) begin working on the plastic mold. This will take about a month, during which we plan to leave China and get proper sleep, nutrition and some sun! The plan is to come back to see the finished mold and start making parts. Launch is getting nearer and nearer. And things are hectic as we're now in total war with the real estate agent after all utilities in the house are breaking and they aren't fixing anything, and now the lights go out if you try to turn on the aircon.

We still have one little problem with the overmolding of the motors, we know how to fix it manually but we don't want this to be a headache every time or to rely on Mr Tang to do precision work, so we've obtained incredible industrial adhesive which can withstand 300C temperatures and won't melt in the mold... long story...

RANGE

Although the lengthy tweaking to extend range on the remote and receiver was a success, and the new setup can now be put together easily with these new PCBs, we did go a bit overboard reducing the ground plane! So the new PCBs are still not the very best we can do. Our hand-tweaked prototype is still 10-15% better. We will likely make another round of PCBs just to see if we can optimize further by re-extending the ground plane slightly (especially since we need to move components around). This won't delay launch as the plastic mold phase will now begin.

BIG PICTURE

Overall this product has now reached maturity; we've gone through the "doesn't frigging work" stage, the "glitches" stage, the "not good enough" stage, and now it's pretty much shiny and perfect and we're just optimizing left and right but basically everything we've put in this product is far better than it has to be to be commercially viable... We really made it with passion, so we hope to get much positive feedback when we start fulfilling orders!

IN THE NEXT EPISODE...

We're getting black overlay samples! Pictures will be posted.

Comments

Post new comment

|

I'm telling ya man.. Clear is the way to go.