|

2010-06-07 02:58:42 (8213 views) This is a photoshop mock-up of what the remotes would look like in black and white, with the current overlay design. Not shown are the LEDs, and the possible use of silver/mirror color for printing (perhaps only legible on the black background).

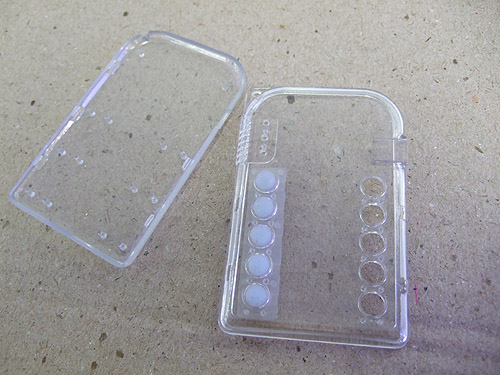

2010-06-04 11:00:24 (9800 views) Full day at the plastic factory!! Very nice stuff...

Polycarbonate prototypes... very nice finish for a machined part, although the new machine shop screwed up a few spots and we can't put the PCB in the receiver (but they are making a new piece free of charge to fix this).

...

2010-06-02 03:24:24 (7547 views) In this big mess of laws, regulations, manufacturing and hardware, the few embedded software programming parts with which we used to struggle have come to seem trivially easy. However, there's one small and mean programming task with teeth we're finally attacking and that's the part where we allow you to reprogram the DL2K-LINK without external hardware.

...

2010-06-02 02:48:59 (7099 views) Click to enlarge.

Quality is very high! This is the result of testing out MANY companies... not everyone is reliable here in China but if you're willing to put in the hard work you will find some rare gems of quality and reliability.

...

2010-05-30 07:44:03 (7625 views) 1. May have eliminated the need for the ferrite bead by implementing very simple EMI suppression circuitry directly within the motor overmold; this helps keep the arousal inducer small. For a definitive answer we'll have to wait until our final day at the EMC lab where will we obtain all the compliance test results (and destroy a few units in the process thanks to the european LVD requirements). This is the last thing that must happen because we cannot modify the product's hardware after this or we'll have to retest everything (few hours of testing cost several thousand dollars).

...

2010-05-27 10:53:02 (7584 views) Regarding the safety of stainless steel electrodes:

"Chromium can exist in four states. Metallic, divalent, trivalent and hexavalent. In some compounds chromium is in the hexavalent state (valence of +6) and many of these compounds are hazardous. The current European RoHS directive bans the use of six substances, one of which is hexavalent chromium. The ban on hexavalent chromium targets primarily corrosion resistant coatings, such as the chromate conversion coatings applied to zinc plating. Metallic chromium found in stainless steel is not a RoHS substance.

[...]

In stainless steel, chromium is in the metallic state, which is not hazardous."

|