|

2011-01-26 12:08:31 (13342 views) We've been talking about a surprise regarding the courses. And as you know... we don't use the word surprise lightly! First it was the accelerometer. Then the arousal inducer. Then the 007 packaging... but now with a completed product and an eye on the courses we've accomplished something even more interesting.

We've hired one of the most talented erotic comic book artists out there to produce illustrations for our upcoming courses! The courses will have no explicit content, but we chose this person because of her skills in drawing human figures.

As a test, she's produced one illustration for us. It's not complete yet (the most interesting half is missing, and it still needs shading) - but take a look.

This artist is one of the very few if not the only female professional erotic comic book artist (that we know of at least) and she is definitely familiar with power exchange (she shows up for exhibitions wearing latex...)

We're now talking to her about how much publicity she wants to have on our site. Hopefully we'll be able to introduce her sometimes soon.

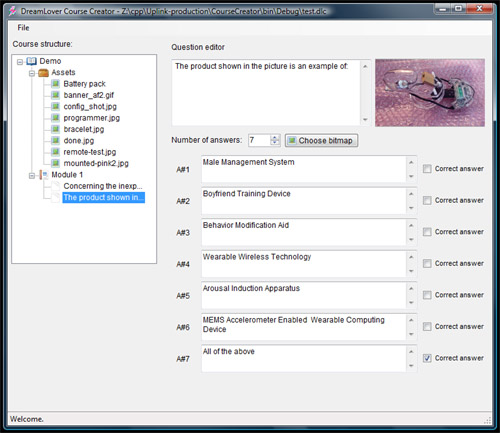

2011-01-24 11:54:44 (12016 views) COURSE CREATOR

As we patiently wait for the many shipments to reach our warehouses we're already busy coding the DreamLover Course Creator, an application which will allow creation of course modules of different types, packaging of custom and pre-made modules into courses and more.

A preview version of this software will be available for download soon.

COURSES

The Education Committe members have spoken to us, both publicly on the forum and in private, with regards to areas in which training help is most urgently needed. It won't be easy to package so much material in our first course, so we will probably agree to a small subsection of what is to be covered and start from there. Creation of our first course will begin as soon as the Course Creator is sufficiently complete.

2011-01-15 00:50:31 (14341 views) We've left China and are now living in South Korea. The differences are enormous. In China, people spit loudly inside the elevator, on the escalators in supermarkets, on the street. In Korea, people disinfect their shopping carts with UV light in special boxes at the supermarket. In China, people throw paper in a basket near the WC when they go to the bathroom, then dispose of that paper every 3 to 6 days. In Korea, the toilet seat is kept warm electronically, emits a pleasant beep when you sit on it, and it's got buttons for different types of water jets.

But the biggest difference is that our new apartment is heated! Southern China apartments have no heating and we freaked out when we noticed we were starting to skip showers for the cold (you could literally see your own breath even sitting in front of the PC at home).

...

2011-01-06 10:53:34 (14452 views)

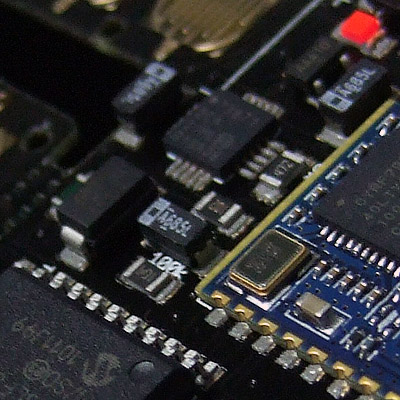

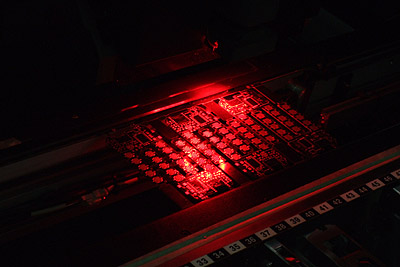

2010-12-28 12:27:26 (15053 views) As you know if you've watched the video two posts below, we're back from the PCB assembly factory with pristine, immaculate, wonderful boards. ESD resistant, gold plated, oven-baked, pick-and-placed, in other words, just about perfect.

The story of how we managed to obtain results like these at a Chinese assembly plant where underpaid workers living and eating on site work with a massive sleep debt and terrible hand soldering equipment, is not for the weak of heart. We had to work day and night with the engineers. We had to sleep near the factory for two nights. We risked going home with nothing - no boards, and wasted components. We even had an emotional breakdown after two sleepless nights.

We are now home and feel like we've come back from the depths of hell.

Read on if you want the insider story!!!

...

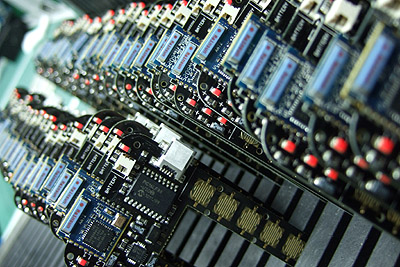

2010-12-28 10:03:22 (13931 views) Some shots from our automated assembly run

|