| << return to blog entries

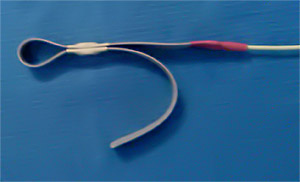

2010-04-03 17:16:13 (6227 views)  Ladies and gentlemen, you are looking at a prototype of the most compact, most advanced rubber electrode ever created (to our knowledge). Ladies and gentlemen, you are looking at a prototype of the most compact, most advanced rubber electrode ever created (to our knowledge).

Three high tech materials are being used here: low resistivity conductive rubber, a strong type of conductive glue, and high grade neodymium magnets. - The cable is attached to the conductive rubber strip with very strong conductive glue

- The conductive strip has two strong neodymium magnets which can be moved along the length of the strip for best fit and create a loop of the required size

- Resistance is only 0.35 ohm/meter (if we understood the specs sent to us) - essentially no resistance at all for our purposes

The amazing thing is that this manufacturer is somewhat of an inventor... he came up with the conductive glue idea. And he found a way to avoid creating a mold by using a simple conductive strip with two additional rubber loops to keep the magnets in place but allow adjustment.

Now, his photography skills are, let's say, average - so we'll need to get these samples, do some testing and take better shots. It is not clear how much these rubber electrodes will end up costing, or how they will be mounted, but it seems clear that - either prior to launch or shortly after that - we will be able to offer an alternative solution to drilling the hole in the CB6000 and the metallic electrode assembly. This is not a priority really, but he's been working on these things hoping to get an order so ... why not take a good look!

Also... is this a definite improvement? More of a diversification really. This type of electrode is obviously not tamper-proof. This is mainly just an announcement that we've found a few ways to play with rubber electrode attachment and positioning - what this will mean in terms of a final solution for the DL2000 is not yet clear. We may go with a completely different shape, for instance something that looks like TENS pads, with an embedded neodymium magnet - that would allow mounting to a CB6000 without the hole. Again, low security compared to our main electrode mounting technique which involves the stainless steel parts.

For now we just want to test this, and make sure the DL2000 pulse can be delivered using this part. More when these parts are received.

Comments

Post new comment

|