| << return to blog entries

2010-03-18 08:58:59 (3467 views) Moving to China is starting to pay off BIG TIME. Please scroll down to see tons of pictures (products, molds, factory machinery... everything!!!)

Let's start from the beginning. Left at 9am and took a taxi to the local bus station.

--

The bus ride was not very interesting...

Finally we met our hero Jason, who's making a pretty good living with his business and drives a BMW surrounded only by old broken down cars and people on bicycles!

He explained that these 1$ flags make his car look like some communist party diplomat's - and prevent him from getting any traffic fines!! :)

After a quick stop at KFC which is the lesser evil out there in terms of food, we proceeded to his factory. Here things got a lot more interesting!

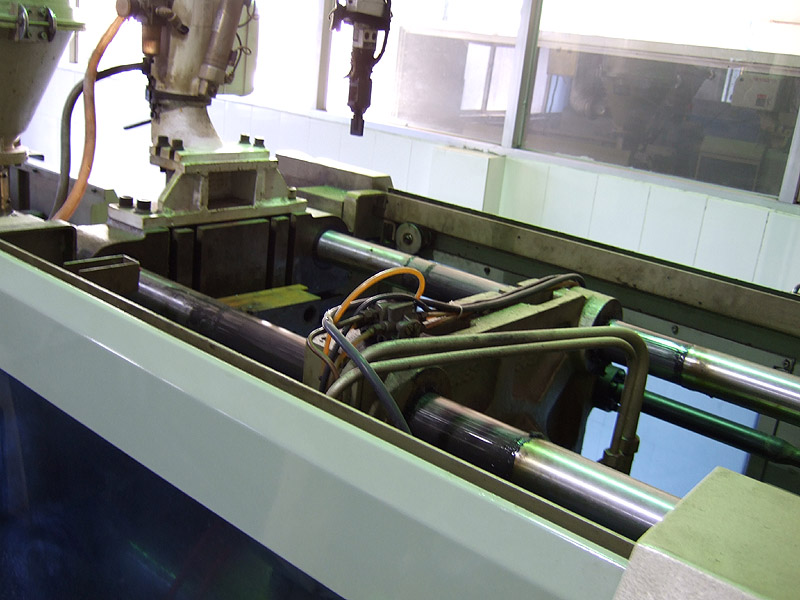

Huge machines everywhere, looking very expensive and professional...

These machines do look really rough and bulky - but the high technology goes into allowing these huge and heavy parts to move with sub-millimetric precision. Many pieces of a machine of this kind - pieces that you could hold in one hand - cost more than a car (but not Jason's perhaps).

It is much clearer now why even a small piece of plastic takes tens of K to create!

The machines are of course supplemented by tons and tons of cheap labor. You can't help feeling guilty when you see the working conditions of workers here. If the product is successful we will personally hand out some bonuses to the employees here... we really appreciate their help!

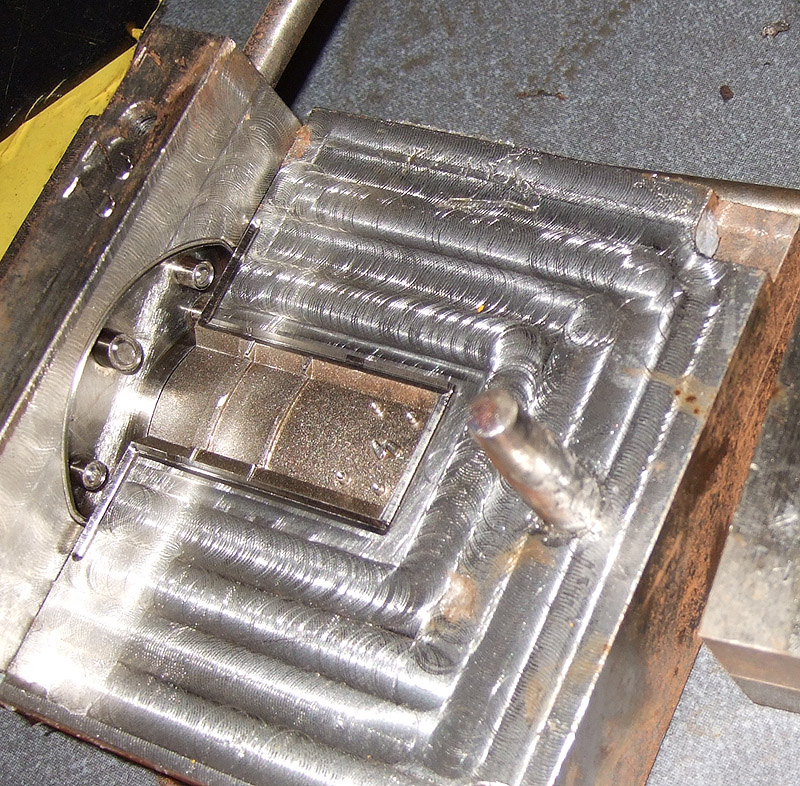

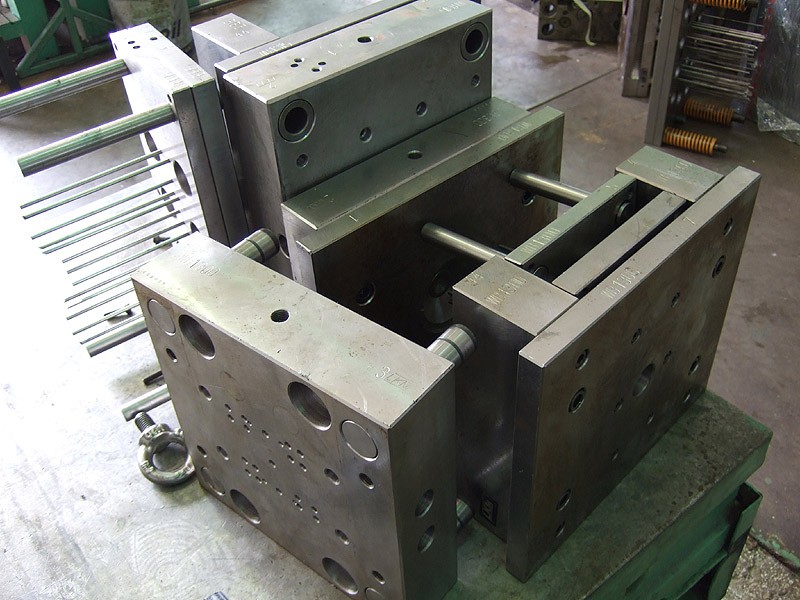

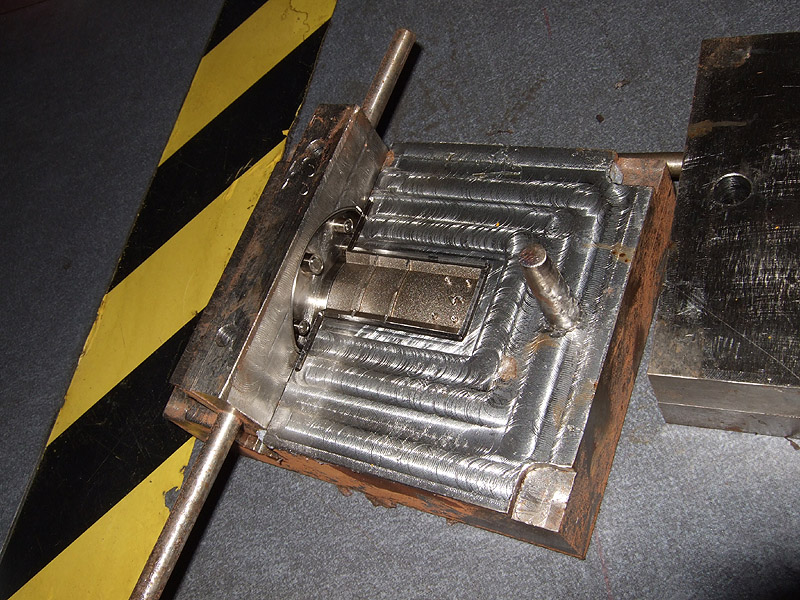

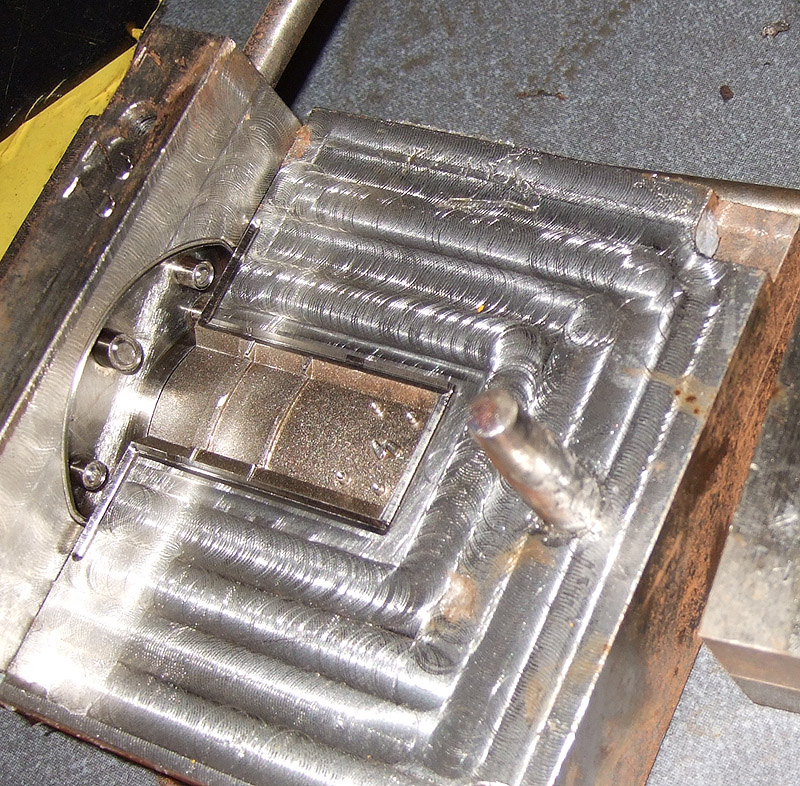

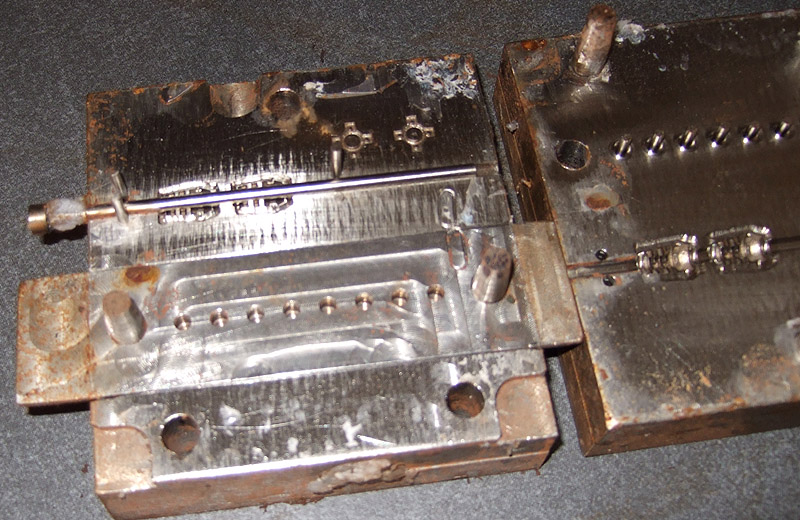

All right... so you want to make a small light-weight piece of plastic... and they charge you 10 grand for tooling. But what's this tooling thing??! Here's what the molds look like. Would you like a bag to take that home?

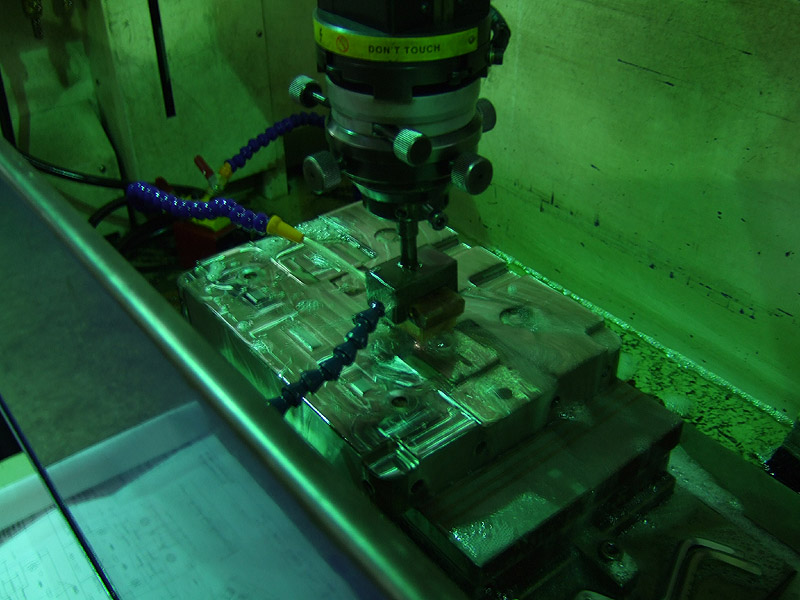

The molds are usually carved with the big machines you saw above. However at times computer controlled drills cannot create fine details. So more heavy duty machines are used which create electric sparks to carve the material with very high precision.

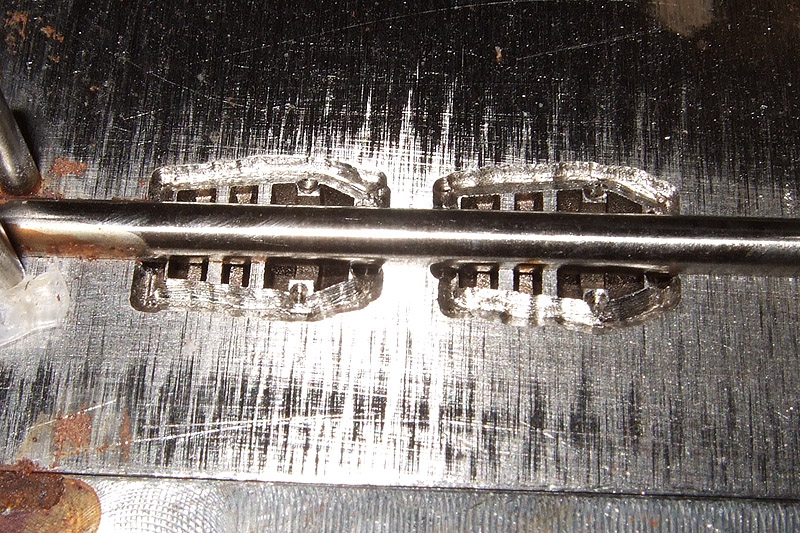

Go figure which of the machines above is the spark one... but the electrodes look like this:

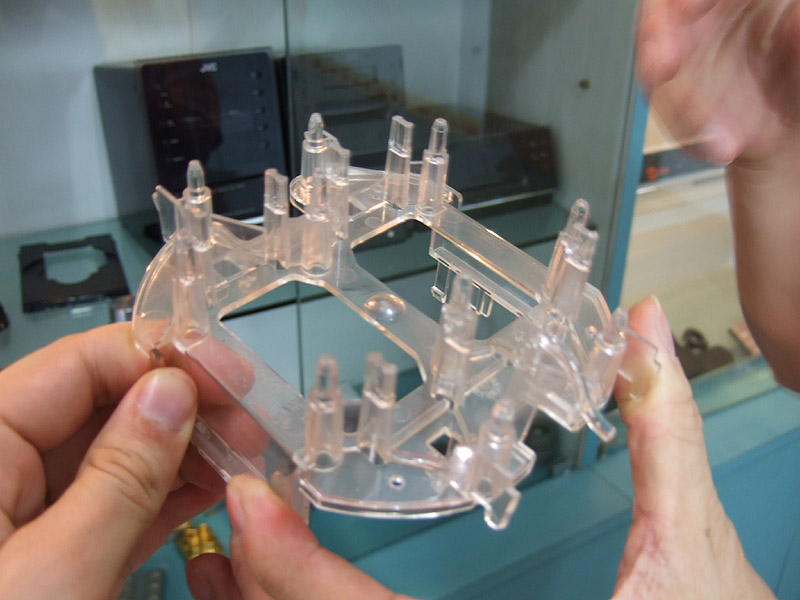

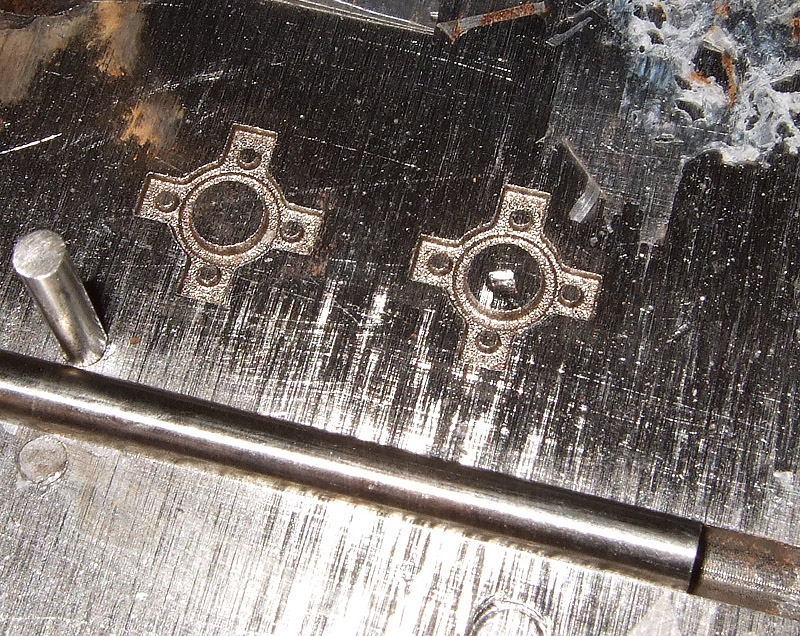

With these machines you can make anything you want. From cool knobs (mold on the left, final product on the right)

to meaningless pieces of plastic which may have meant a whole lot to the guys who designed them :)

This is a die cast metallic piece

Another critical component here: lots and lots of tea to keep everyone working!

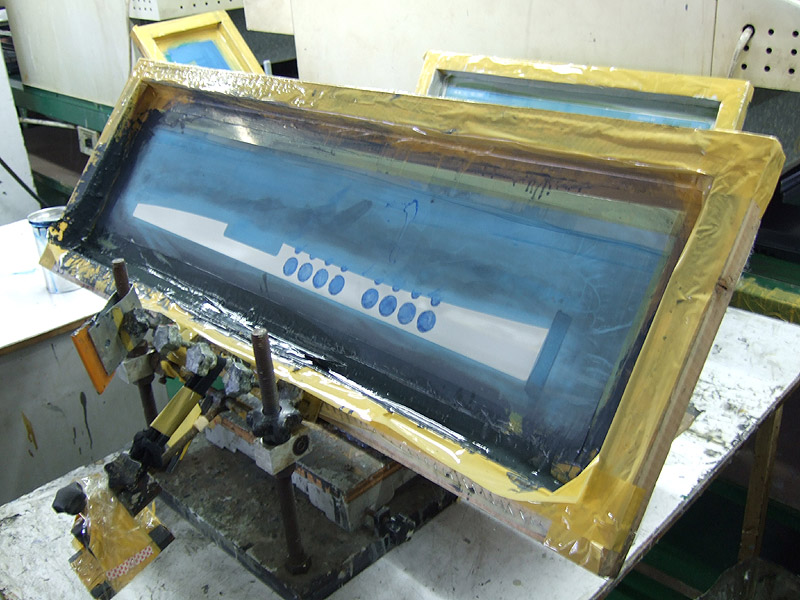

Now we proceed to the printing room...

Someone must have warned them we were coming, because they put our logo on the wall.

Let's take a look at some screen printing

If you thought the guys above had it bad... you can't even breathe in the closed rooms because of the smell of paint and chemicals.

The results of all this hard work are, however, very impressive. These pieces use either pad printing or silk screen printing:

Here's a cool nickel plated plastic part. Pad printing works even though the surface has very small grooves.

This is an average production run piece. There are so many pieces they have to carry them out with trucks.

That explains why no one wanted our business of a few hundred units!!! Thankfully, Jason is there for us.

--

Next stop is the other factory where rubber parts are created. But first we must stop and buy some properly sized cables to test the waterproofing. This place is a total electronics heaven, with heaps of parts of all kinds - bigger than Bangkok's Ban Mo, bigger than Japan's Akihabara, or Taiwan's Guanghua Shangchang or Korea's Jong-no 3ga!

They did, of course have cables - lots of.

So we arrived at the rubber factory...

Here they make cool stuff like:

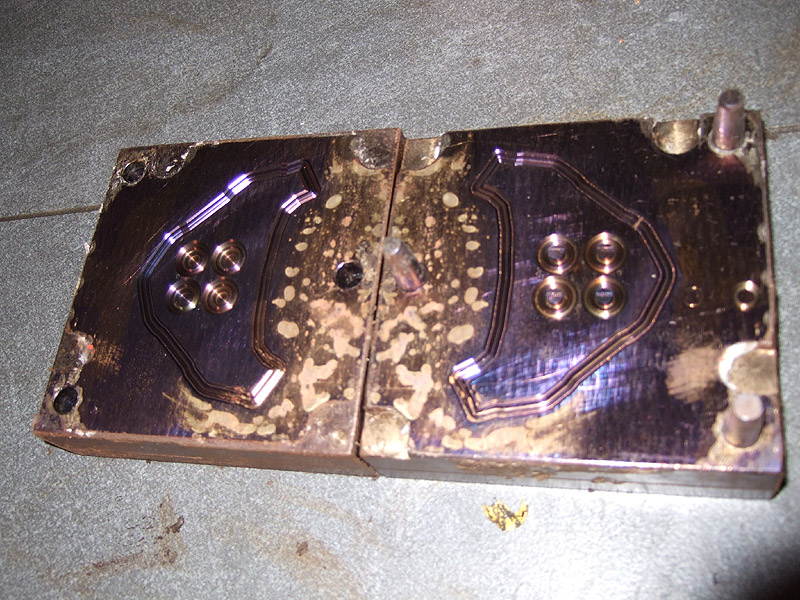

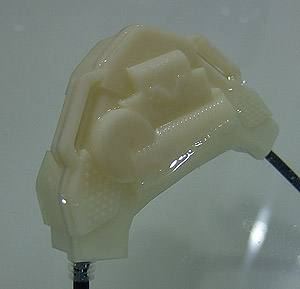

And here we found OUR DREAMLOVER 2000 MOLDS!!!! Ladies and gentlemen, here they are in all their humble glory. (Sorry for the flash photography, unfortunately the molds were in a dark corner and we couldn't take very good pictures)

Ok... rubber attachment!

The grommets!

The star shaped ring terminal cushions!

And one of the machines that pump the rubber at a given temperature and pressure...

Now let's not forget the O-ring, essential waterproofing component.

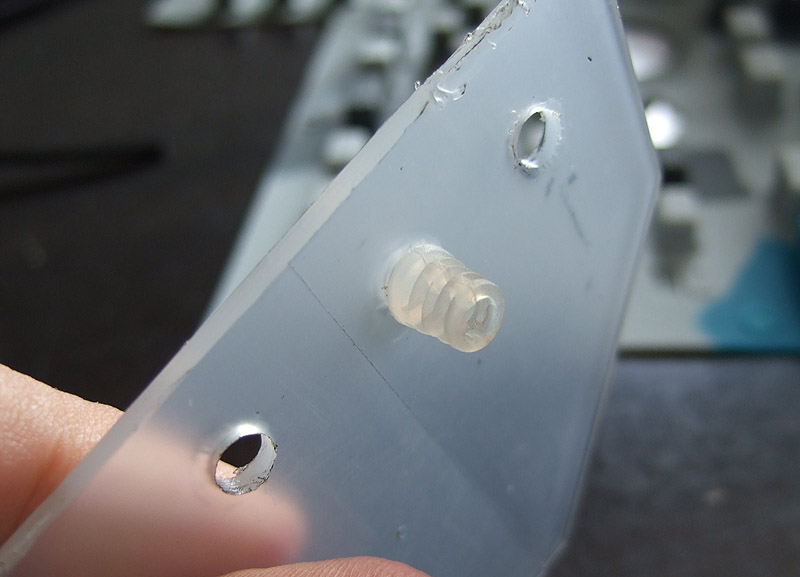

So without further ado, let's get to the waterproofing test! First of all we enlarged the holes on our enclosure prototype so that the grommets could be inserted.

Testing different hole sizes...

Grommets GO.

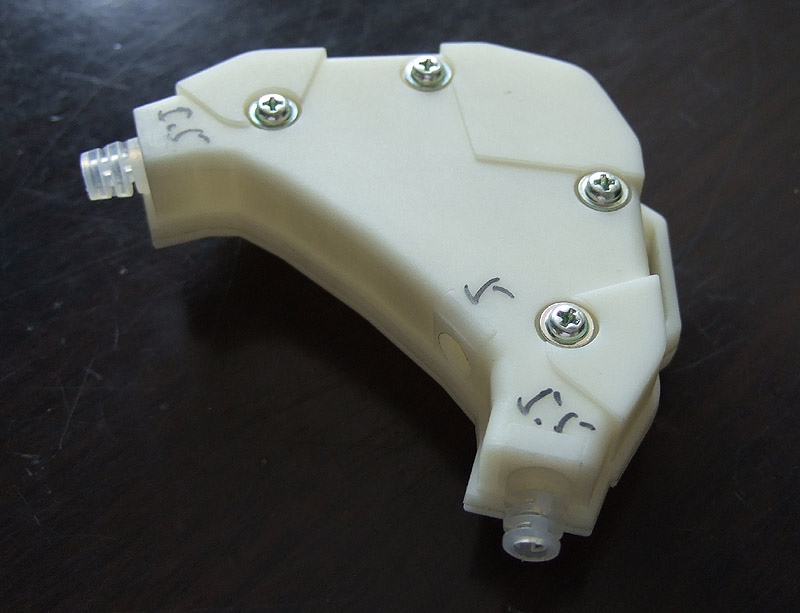

Screw o-rings, and main o-ring GO.

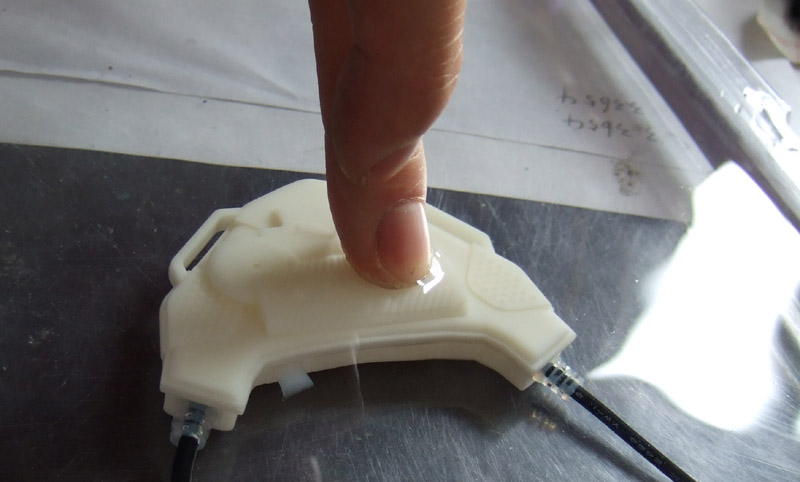

And.... submerge!!!

RESULTS

All right, the good news is that only a tiny bit of water went through. This is almost surely due to the fact that the 3.5mm diameter cable is not thick enough for the grommet.

The 4mm cable is too big to fit inside the grommet (can't push it through). So we will probably have to make the grommet's hole a bit narrower and use the 3.5mm cable.

We'll post new updates about waterproofing soon. This is not going to be very difficult, we just need to do some tweaking to get it just right. It is definitely not an exact science.

More worrying is the present status of the surprise (doesn't work). We have a plan though. Jason is being very very patient in brainstorming with us. The technology required by the surprise is something that has apparently never been attempted before!! Soon you will know everything about the hurdles we're going through to get it to work. Spent over an hour on the machines trying different systems and ended up having to make 2 extra mini-molds.

We also upgraded the product by ordering PAD PRINTING on our rubber keypad. Extra cost but wow - so professional. We have no clue what icons we should use for the keypad... we've got 3 strength buttons... timer buttons... we'll probably make a list and let you come up with ideas on this forum.

We're incurring many additional tooling costs as we go forward. We were warned that product manufacturing always takes at least 3 times as much money as planned and considering these latest tweaks that turned out to be almost right. We're pretty much broke but we're so excited at this point we could sell our underwear to get this working 100%.

Arrived back home at 9pm and started resizing images and posting this update... haven't even created thumbnails so this post may be heavy...

Some video material showing the machines and huge robot arms in action is coming up soon (on Metacafe... youtube is blocked here).

Today was a very exciting day :)

Comments

Post new comment

|

french dyonisos